Coolant thru hydraulic chucks.

Can you use standard end mills or do they have to have a coolant channel in the tool?

Regards

Morris

The Case for Hydraulic Chucks [5 Benefits]

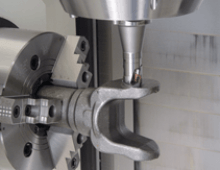

Instead of relying on a nut, collet or extreme temperature to clamp the body of a tool, hydraulic chucks use fluid. By compressing an internal membrane in the holder body, the hydraulic fluid applies uniform pressure around the cutting tool. This fundamental design feature brings us to the first asset hydraulic chucks bring to the table: concentricity. The evenly applied gripping provides more control and consistency than a collet or manual tightening of a nut.

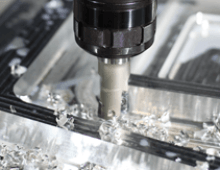

Concentricity

Concentricity is especially valuable in high-speed machining applications where depth of cut is relatively shallow. Preventing even one of a cutter’s teeth from taking more of a load will extend tool life and reduce costs. Standard hydraulic holders offer exceptional runout, while our Ultra Precision Type measures staggering runout accuracy of one micron at 4xD. It stands to reason that hydraulic holders were originally designed for high-performance drilling/reaming applications and lighter milling.

Setup Flexibility

Aside from stellar cutting performance and precision, hydraulic chucks offer setup flexibility. When assembling a tool, one of the best principles to follow is to make every tooling assembly as short as possible. The shorter the tooling, the less room for error. It also makes for easier access to tricky pockets when advanced workholding or extra axes aren’t an option.

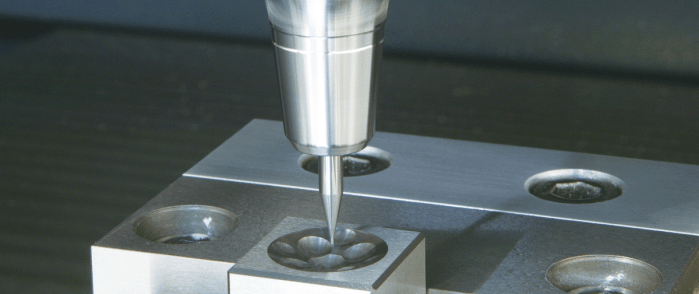

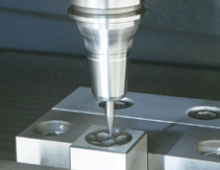

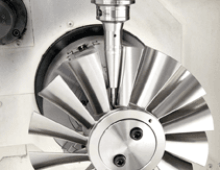

Smaller Nose Diameter

Compared to more general-purpose holders, hydraulic chucks have a smaller nose diameter relative to the tools they hold. This is critical, as these holders allow a further reach into mold cavities or other tricky work envelopes with less interference and without using extensions that can sacrifice rigidity. These characteristics make hydraulic holders especially effective in delicate 5-axis machining, finishing especially.

Our Super Slim Type, for example, features nose diameters as small as 14 mm (.551"). We’ve been able to design the hydraulic system with a very tight tolerancing of the bore, allowing for clamping down to three millimeters and spindle speeds up to 45,000 RPM. Meanwhile, the natural damping characteristics of the hydraulics are especially advantageous in these extreme scenarios as well.

Coolant Delivery

There’s also the option to have coolant delivery directly to the cut with hydraulic holders. Ideal for smooth, stable finishing operations our Jet-through Type allows for conversion between jet-through and center-through delivery for an improved surface finish and tool life.

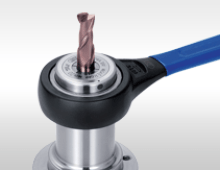

Quick and Easy Setup

Setups aren’t only flexible, they’re also quick and simple. A single hex key wrench is used to clamp or loosen the cutting tool, making it easy to swap cutting tools at the machine or offline without the need for any special equipment.

Short- and Long-term Advantages

Ultimately, hydraulic chucks will cost you a little more. But as the old adage goes, you get what you pay for. Shrink-fit holders boast similar performance and cost less up front, but that doesn’t factor in the cost of heating/cooling equipment and time. ER collets or side lock end mills may remove a lot of material, but if any precision or consistency is required, hydraulic chucks are the better option. Plus, their simple handling and relatively low maintenance make life easy on machinists.

If you have work that demands accuracy or are looking to give your 5-axis capabilities a boost, hydraulic chucks are definitely worth some consideration. Learn more about the different types of hydraulic chucks and explore our full offering of these impactful holders.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.

Comments

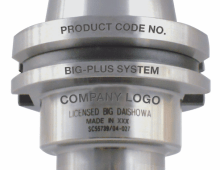

BIG DAISHOWA Inc.

Fri, 04/01/2022 - 16:18It's perfectly okay to use a standard end mill if you're dry cutting, using a reduction sleeve that allows coolant to flow around the tool, or using a chuck that has a "J" in the name, which designates jet coolant.

David Meng

Thu, 11/03/2022 - 10:25Dear Sales /Application team,

May I ask if the hydraulic chuck can be used for 1.6 mm to 2 mm drills or reamers, and the cost for the chuck?

Thanks,

David Meng

BIG DAISHOWA Inc.

Thu, 11/03/2022 - 10:36Hi David,

I'll pass your inquiry along to our team. You will receive a response to the email address you provided. Thanks!

MORRIS DAGLEY

Fri, 04/01/2022 - 15:07